How an Optical Fibre Diameter Analyser Improves Quality Control in Fibre Production

The combination of an Optical Fibre Diameter Analyser into Fibre manufacturing procedures stands for a considerable development in quality control methodologies. By using real-time, exact measurements of Fibre sizes, this modern technology resolves the essential demand for consistency in manufacturing requirements.

Importance of Fibre Diameter Measurement

Precise measurement of Fibre Diameter is essential in the area of optical Fibre modern technology, as it straight affects the performance and integrity of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying ability, attenuation, and overall transmission performance. Accuracy in determining Fibre Diameter guarantees that the optical residential properties are preserved within defined tolerances, which is vital for ideal signal integrity.

Variants in Fibre Diameter can lead to boosted losses because of scattering and modal dispersion, affecting the high quality of information transmission. In high-speed communication systems, such disparities can cause substantial degradation of signal high quality, resulting in information errors and lowered efficiency. Furthermore, regular Fibre Diameter is necessary for compatibility with ports and splicing modern technologies, which are essential components of Fibre optic networks.

Quality control procedures in Fibre production heavily rely upon precise Diameter dimensions to make certain compliance with industry requirements. By applying durable dimension methods, suppliers can enhance product integrity, reduce waste, and improve overall system performance. Thus, the relevance of Fibre Diameter dimension can not be overemphasized, as it functions as a keystone in the development of optical Fibre innovation and its applications in contemporary communication networks.

Exactly How the Analyser Works

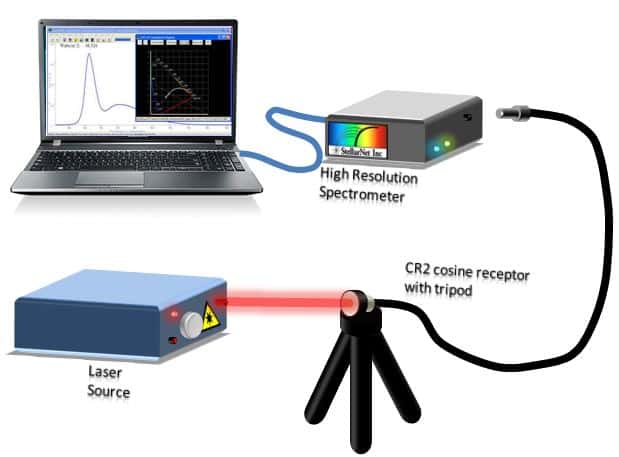

The effective dimension of Fibre Diameter counts on sophisticated analytical techniques that make sure accuracy and reliability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser uses a mix of laser modern technology and progressed picture handling algorithms to precisely analyze the Diameter of fibres as they are created

Originally, a laser light beam is directed at the moving Fibre, developing a cross-sectional shadow. The analyser captures this darkness using high-resolution cams placed tactically along the assembly line. The captured pictures are then processed in real-time to identify the Fibre's Diameter with extraordinary precision.

The system utilizes advanced formulas that represent various aspects, consisting of variations in light strength and environmental problems, to boost measurement integrity. It can spot minute changes in Diameter, such as variations that might take place throughout the production procedure.

Additionally, the analyser is qualified of handling multiple fibers concurrently, boosting throughput without compromising accuracy. By offering instant comments on the Diameter, the Optical Fibre Diameter Analyser plays a vital function in keeping strict high quality control criteria, ensuring that the end product satisfies market specs and client needs.

Benefits of Real-Time Tracking

While typical approaches of keeping track of Fibre Diameter frequently involve time-consuming post-production checks, real-time tracking substantially improves the efficiency and high quality of optical Fibre manufacturing. optical fibre diameter analyser. This proactive method permits makers to identify variances in Fibre Diameter as they happen, instead of waiting till manufacturing is complete to analyze top quality

By continually determining the Diameter during manufacturing, suppliers can make sure that the fibres fulfill rigid requirements, bring about reduced variability and improved consistency. Real-time surveillance also allows prompt restorative activities to be taken, reducing waste and avoiding defective fibers from going into the supply chain.

Moreover, this innovation facilitates web enhanced data collection and analysis, providing understandings into production fads and prospective areas for improvement. Such data-driven decision-making empowers suppliers to optimize processes and maintain high requirements of top quality control.

Additionally, real-time tracking promotes a society of continual renovation within the manufacturing setting. Employees are extra engaged when they can see the effect of their operate in real-time, bring about heightened responsibility and a dedication to quality. Overall, the application of real-time monitoring systems in optical Fibre manufacturing equates to premium product quality and boosted client satisfaction.

Influence On Manufacturing Effectiveness

Executing optical Fibre Diameter analysers considerably improves production effectiveness by simplifying the production procedure. These tools promote continual tracking of Fibre Diameter, permitting makers to identify discrepancies in real-time. By recognizing disparities without delay, assembly line can be changed promptly, reducing downtime and lowering the probability of creating defective products.

Furthermore, the combination of these analysers into the manufacturing operations allows better source allocation. With precise Diameter dimensions, drivers can enhance product use, making sure that sources are not thrown away on flawed fibres. This accuracy also adds to much less rework and scrap, eventually reducing production expenses.

The automation visit the site offered by optical Fibre Diameter analysers reduces reliance on hands-on assessments, which are usually taxing and susceptible to human mistake. Because of this, staff members can concentrate on even more critical jobs, improving overall productivity.

Moreover, the information produced from these analysers can inform procedure renovations and assist in better decision-making. By assessing patterns in Fibre Diameter variants, makers can execute aggressive measures to boost production strategies and preserve constant high quality. In recap, optical Fibre Diameter analysers play a critical duty in improving manufacturing performance, leading to better output and raised success.

Study and Success Stories

Across different markets, instance studies highlight the transformative effect of optical Fibre Diameter analysers on production processes. One famous instance is a leading telecoms company that faced challenges with inconsistent Fibre diameters, causing raised rejection rates. By integrating an optical Fibre Diameter analyser, the business accomplished real-time tracking of Fibre dimensions, leading to a 30% decrease in flaws and considerable price savings.

Furthermore, a research organization concentrating on sophisticated products utilized optical Fibre Diameter analysers to improve their experimental procedures. The analyser's capacity to provide comprehensive insights right into Fibre uniformity enabled the development of ingenious products with enhanced performance qualities.

These success tales underscore the important role of optical Fibre Diameter analysers in boosting quality assurance, boosting production efficiency, and driving development throughout diverse industries.

Conclusion

In conclusion, the Optical Fibre Diameter Analyser plays a crucial role in improving quality control within Fibre production. As shown through different instance researches, the analyser proves necessary for achieving superior product high quality in Fibre production.

The execution of optical Fibre Diameter analysers enabled for stringent high quality control, making sure that the created fibers met exacting industry requirements.In verdict, the Optical Fibre Diameter Analyser plays an essential role in improving top quality control within Fibre production.